Kaliyo Touch screen cover glass

Kariyo is a factory that produces etched AG anti-glare glass materials and processes touch screen glass cover plates.

Kariyo is a factory that produces etched AG anti-glare glass materials and processes touch screen glass cover plates.

We sell etched anti-glare AG glass sheet materials to the world, and can also provide chemical tempering, physical tempering, CNC edge grinding, silk screen printing, high-temperature sintering ceramic ink printing processing.

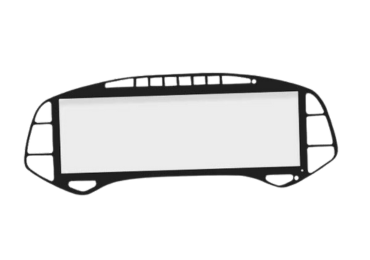

Our products are widely used in automation equipment control panels, POS touch screens, smart home displays, security equipment displays, small home appliance control panel touch screens, agricultural vehicle displays, car displays, new energy vehicle central control screens, new energy vehicle charging pile displays, industrial control equipment touch screens, medical equipment displays, subway displays, tablet computers, industrial mobile phones and other products. It is a main force in the supply chain of touch screen cover glass and etched AG anti-glare glass sheets in China. We have mastered the core technologies of anti-glare glass etching technology and touch screen glass cover processing, and can provide customers with customized products of various shapes and thicknesses. We can quickly respond to small batches and multiple varieties of glass cover plates.

Kariyo's History

Business content

○ According to the usage scenario of your product, we provide you with a design plan for the touch screen cover glass and quickly realize mass production.

○ If you only have a sample of the touch screen cover glass, but do not know the optical parameters or specific production process of the relevant AG anti-glare glass, we can analyze and test it for you free of charge, and produce the same cover glass as the sample.

○ If you already have a satisfactory design, we will produce the touch screen cover glass according to your drawings.

○ The thickness of the touch screen cover glass we can produce is 0.15mm-6mm.The size of the touch screen cover glass we are good at producing is 1-32 inches.

○ The materials we often use: Corning Gorilla Glass, AGC Dragontrail, AGC

soda lime glass, NSG, Schott glass, CSG (Southern Glass), panda glass (Xuhong).

Our team

Our factory covers an area of about 15,000 square meters and has 360 employees, including 1 Ph.D. in chemistry, 4 senior engineers, and 30 QC inspectors. It is divided into two factories, one for chemical etching AG anti-glare glass sheets and the other for glass cover plates. Each factory operates independently, and the general manager of each factory is responsible for its own profits and losses.

Why choose Kariyo?

Our Products