We are capable of undertaking the business of customized products with small batches and a wide variety. more suitable for high-quality customized products.

We are proficient in the multi-color silk-screen splicing technique and can skillfully silk-screen a variety of colors onto the cover glass.

Our factory can process two techniques, namely chemical tempering and physical tempering. which enables us to have a faster delivery and better guarantees the quality.

customize

AG/AR/AF/DLC

- AG↓

- AR↓

- AF↓

- DLC↓

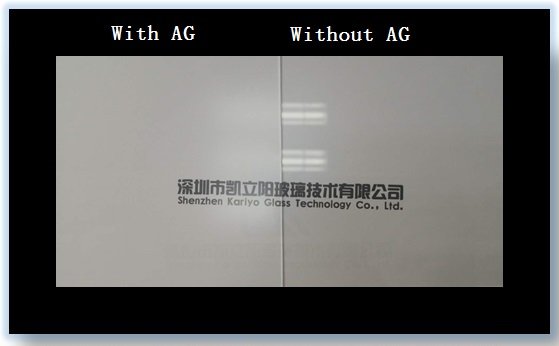

Anti-Glare (AG)

By forming specific microscopic structures or coatings on the surface of materials, the ways of light reflection and scattering can be changed. The specular reflection of light is reduced and the diffuse reflection is increased, thus reducing glare and improving visual clarity. For example, a uniform microscopic rough structure is formed on the surface of the substrate, so that when light enters, it is scattered into diffuse reflected light at different angles, preventing direct light from entering the human eyes.

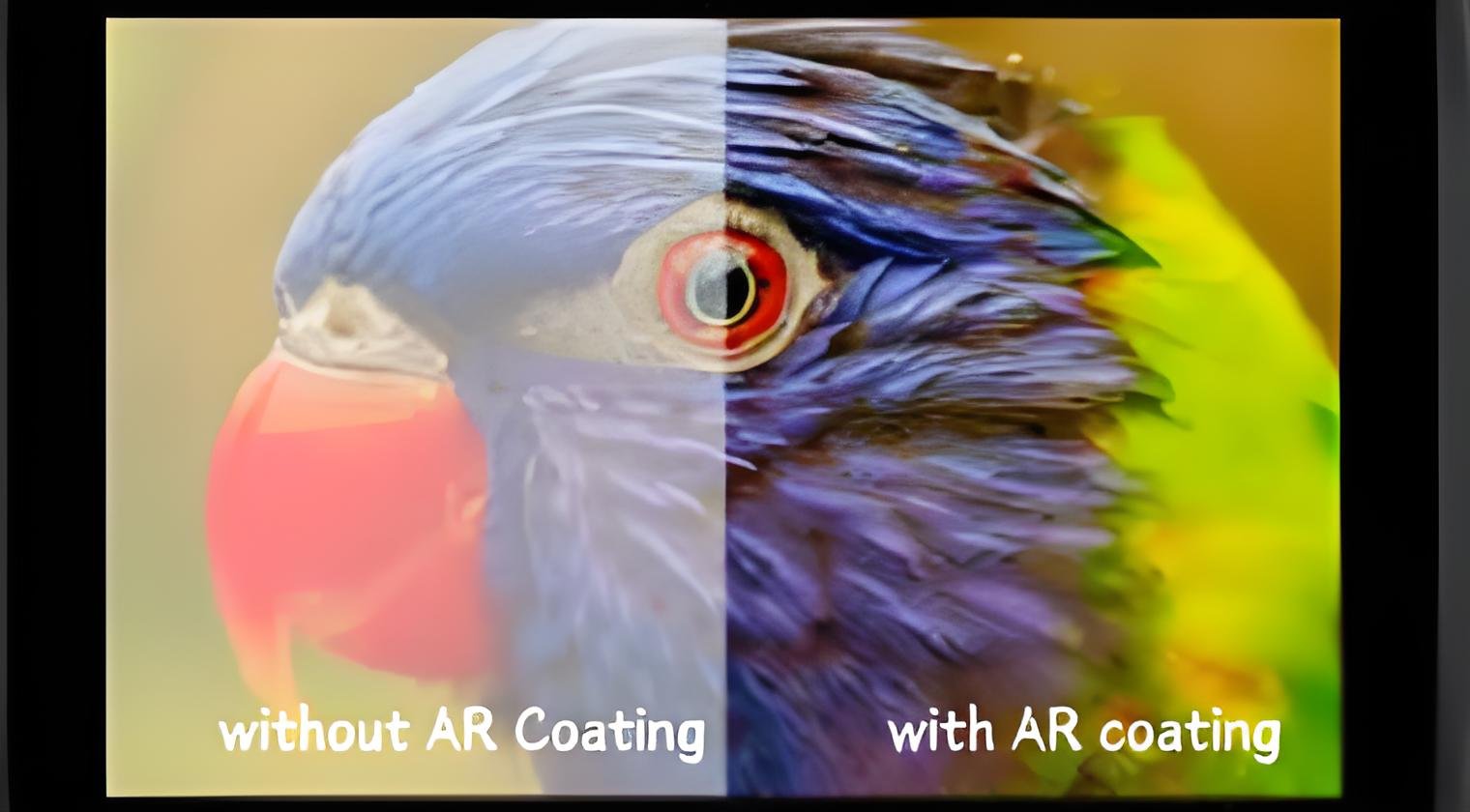

Anti-Reflection (AR)

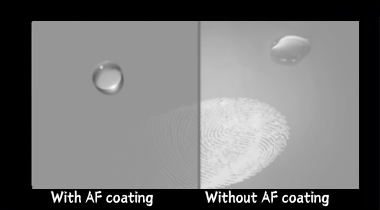

Anti-Fingerprint (AF)

A coating with special chemical structure and properties is coated on the glass surface. This coating usually has a relatively low surface energy, which makes it difficult for secretions such as grease and sweat left after fingers touch the glass surface to adhere. Even if a small amount adheres, it can be easily wiped clean, thus playing the role of anti-fingerprint.

Diamond-Like Carbon (DLC)

Techniques such as Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD) are adopted. Carbon-containing gases (such as methane, etc.) are decomposed and deposited on the glass surface under specific process conditions to form an amorphous carbon film structure. Its structure and properties are similar to those of diamond in some aspects, for example, it has characteristics like high hardness and high wear resistance.

manufacturing and processing capabilities

- Glass Dimension 1″ to 32″

- Thickness: 0.4mm-6.0mm

- Material : Corning Glass , Soda lime Glass, Panda Glass, Dragontrail Glass.etc.

- Shape: customized ( rectangle, square, irregular, round )

- Processes: Chemical etching (AG), CNC edge grinding, chemical tempering or physical tempering, magnetron sputtering coating (AR), multi-color silk screen printing.

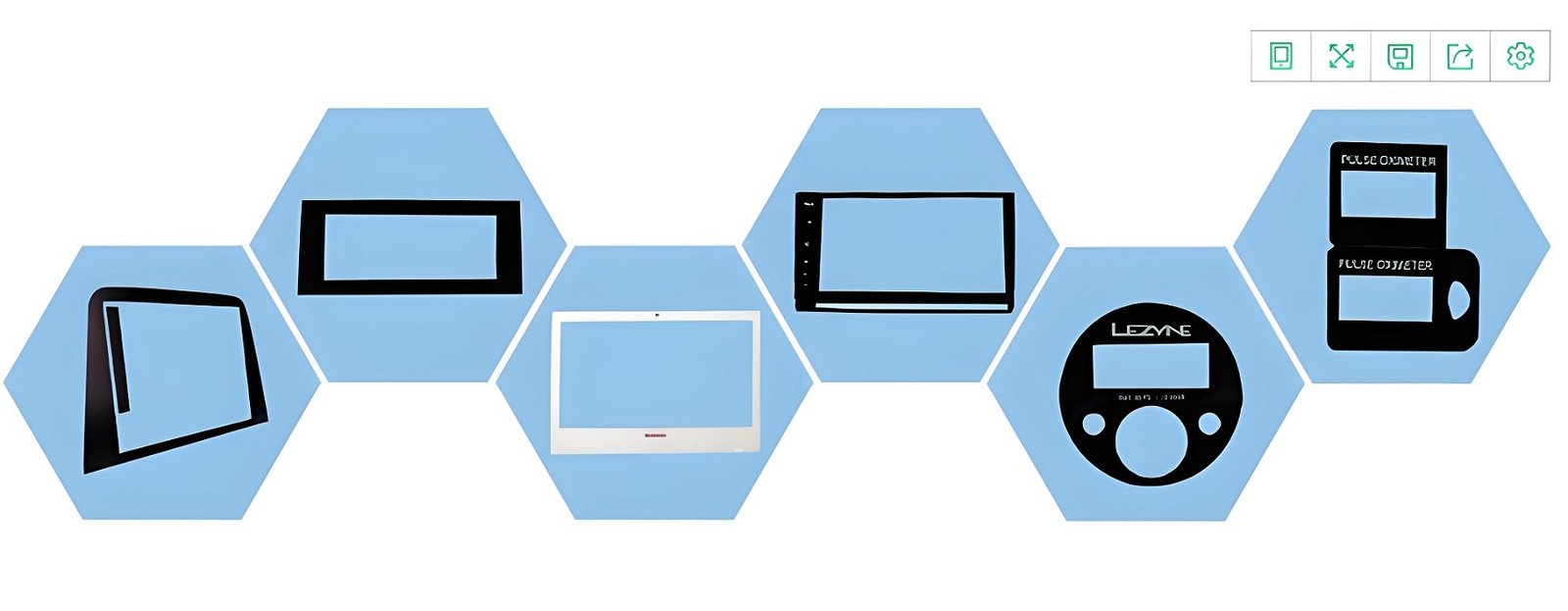

Product Application

The products are widely used in various touch screens.

Our Declaration

- Continuously striving to reduce costs is our task every day.

- Delivering goods on schedule is our mission.

- Ensuring quality is the foundation of our survival.

- Solving customers’ problems is helping ourselves.

- Both customers and suppliers are our important partners.

![]()

Partners

2000+ Project

How to Support Your Business”

Once we have replied to the customer with the delivery date, we will spare no effort to meet it.

We only make reasonable profits, and continuously improve our technology and management to reduce costs, ensuring that our costs are more than 3% lower than those of our competitors.

Customer testimonials

-

Arjun Patelfrom India

Arjun Patelfrom India -

Leo Thompsonfrom Australia Melbourne

Leo Thompsonfrom Australia Melbourne -

Ethan Brooksfrom America

Ethan Brooksfrom America

We started to cooperate with Kariyo in 2019. Kariyo has always taken the initiative to offer solutions with lower costs, which is very beneficial to the progress of the whole project. We hope to work together with Kariyo to create more business opportunities.

We started to cooperate with Kariyo in 2016. Kariyo has always delivered goods on time, which makes me, as the person in charge of procurement, feel very relieved.

We started to cooperate with Kariyo in 2017. Up to now, there have never been any major quality issues, which makes us feel very relieved. Besides, I’m fond of Chinese cuisine. I hope to have more opportunities to go on business trips to Kariyo and initiate more cooperations.