Custom Etched Anti-Glare Glass

Through the etch masking process, we achieve a perfect integration of anti-glare properties and precise patterns on a single glass surface.

- Partially Anti-Glare Etched Glass(Patterns,logo,

- Etched Anti-Glare Glass sheet(max 100 inches)

- Thickness: 0.33-6mm

- Gloss, Haze, Ra, Rz, and Rsm are adjustable

Unveiling the Future of Display Technology: Kariyo's Anti-Glare Etched Glass Solutions

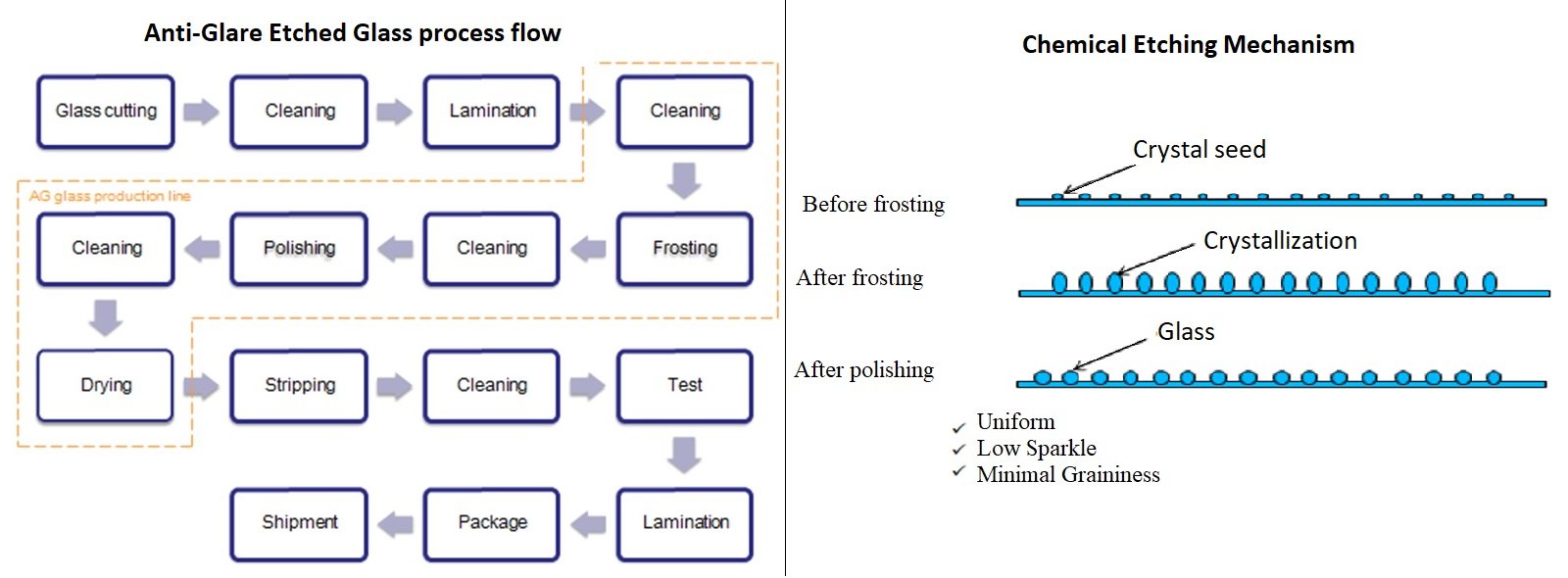

1. Principle and Applications of Chemically Etched AG Glass

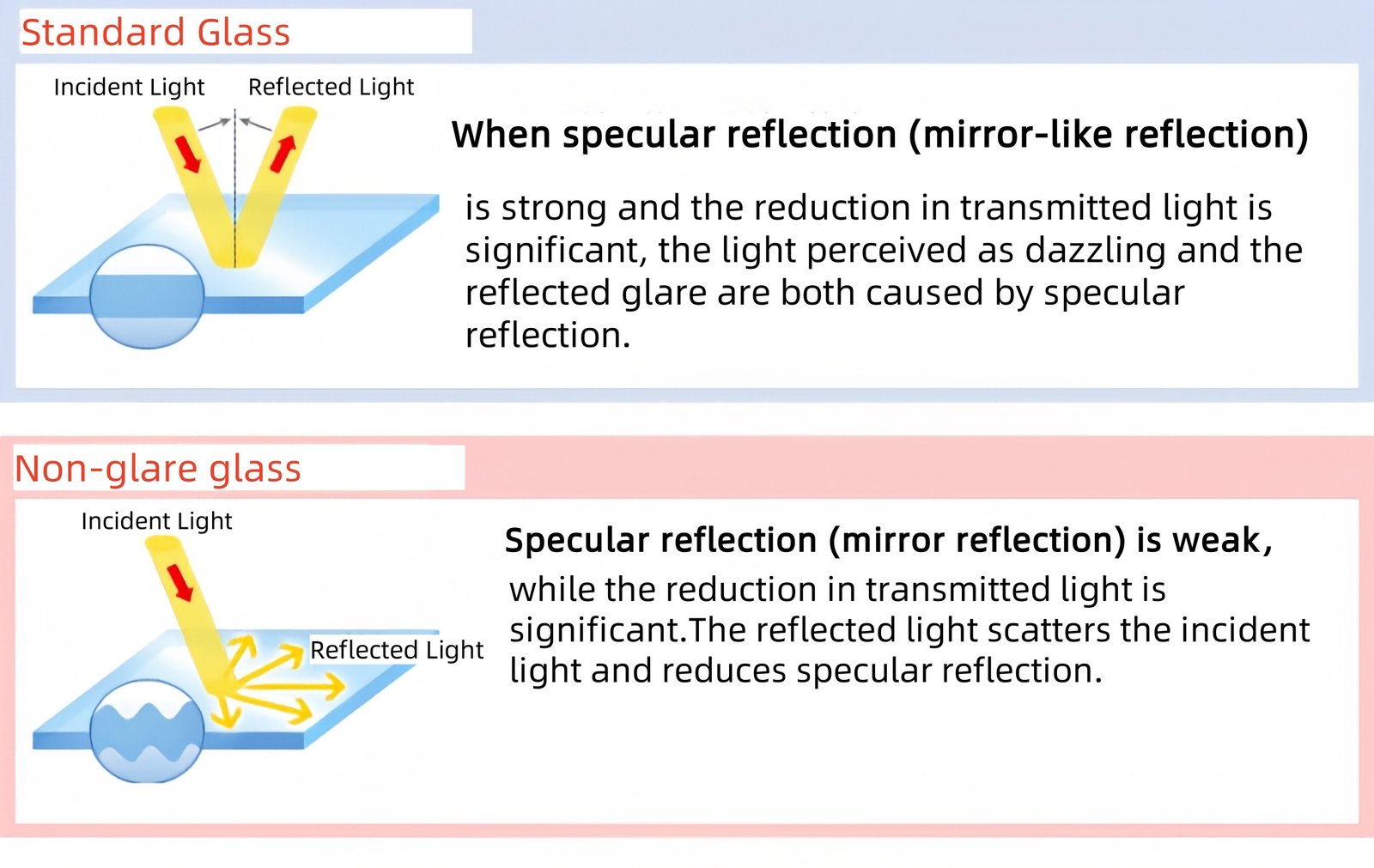

Principle: Kariyo’s AG glass is manufactured through a precise chemical etching process that transforms smooth glass surfaces into micro-roughened, matte finishes. This microstructure scatters reflected light, reducing glare from 8% to below 1% while maintaining high transparency (up to 92% light transmittance). Unlike sprayed or coated AG alternatives, chemical etching ensures permanent modifications to the glass substrate, eliminating delamination risks and enhancing longevity.

Applications:

-

Industrial Control Panels: Ensures readability in brightly lit factories.

-

Medical Displays: Provides glare-free imaging for surgical monitors and diagnostic equipment.

-

New Energy Vehicle Centers: Enhances safety for touchscreens in dashboards and charging stations.

-

Smart Home Devices: Reduces reflections on smart appliances.

-

Public Transportation & Aerospace: Withstands harsh environments in aircraft cockpits and marine navigation systems.

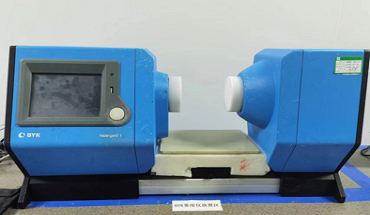

2. Key Optical Parameters: Precision Engineering

Kariyo’s AG glass is engineered to meet exact optical specifications, critical for industrial applications:

-

Gloss (Glossiness): Controlled between 15–130 GU (e.g., 60–80 GU for medical displays).

-

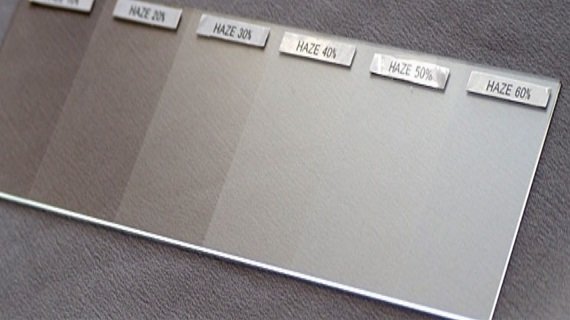

Haze: Ranges from 2% to 70%, balancing diffusion and clarity.

-

Roughness (Ra): Maintained at 0.03μm–1.2μm to optimize light scattering.

-

Distinctness of Image (DOI): Enhanced surface uniformity ensures minimal visual noise.

These parameters are customizable to align with client-specific requirements, ensuring compatibility with diverse industrial environments.

3. Automated Production: Minimizing Human Error

Kariyo’s state-of-the-art automated production lines integrate DCS (Distributed Control Systems) to achieve precision etching and polishing. The process includes:

-

Acid Etching: Controlled by robotic spray systems for uniform micro-structuring.

-

Quality Assurance: In-line sensors monitor parameters like gloss and haze in real-time.

This automation reduces human intervention, ensuring batch-to-batch consistency and compliance with international standards (e.g., ISO9001, ROHS).

4. Advantages of Chemical Etching Technology

-

Durability: Resists scratches, chemicals, and abrasion without coatings.

-

Environmental Resilience: Ideal for outdoor use (e.g., charging stations) due to UV and humidity resistance.

-

Eco-Friendly Production: Utilizes closed-loop wastewater treatment systems to minimize environmental impact.

-

Cost Efficiency: Long product lifecycle reduces replacement needs, lowering total ownership costs.

Why Choose Kariyo?

Kariyo’s expertise in chemical etching technology, combined with our commitment to innovation, positions us as a trusted partner for industrial clients. Our AG glass solutions are tailored to enhance performance in sectors where clarity, durability, and reliability are non-negotiable.

Explore Our Capabilities: Visit Kariyo’s website to learn how our Anti-Glare Etched Glass can elevate your products.

Anti-Glare Etched Glass Standard Parameters

- Tab1

- Material

| Standard Parameters for Anti-Glare Etched Glass in Industrial Control and Commercial Display Applications | |||||||

| Gloss | 25±5 | 50±10 | 60±10 | 70±10 | 80±10 | 95±10 | 110±10 |

| Haze | 26±4 | 11±3 | 8±3 | 6±3 | 5±3 | 4±3 | 3±2 |

| Ra | 0.16±0.04um | 0.15±0.04um | 0.14±0.04um | 0.13±0.04um | 0.12±0.04um | 0.12±0.03um | 0.10±0.03um |

| Tr | ≥85% | ≥85% | ≥87% | ≥88% | ≥88% | ≥89% | ≥89% |

| Parameters for Anti-Glare Etched Glass with High Image Clarity and Low Sparkle for Premium Automotive Displays | |||||||

| Gloss | 50±10 | 70±10 | 80±10 | 95±10 | 110±10 | 120±10 | 130±10 |

| Haze | 15±3 | 12±3 | 10±3 | 8±3 | 6±3 | 4±3 | 2±2 |

| Ra | 0.08±0.03um | 0.07±0.03um | 0.06±0.03um | 0.05±0.03um | 0.04±0.03um | 0.04±0.03um | 0.04±0.02um |

| Tr | ≥86% | ≥88% | ≥88% | ≥88% | ≥89% | ≥89% | ≥89% |

| Typical Parameters for Anti-Glare Etched Glass for Eye-Care Learning Tablets & Mouse Pads | |||||||

| Gloss | 15±5 | 18±5 | 15±3 | ||||

| Haze | 40±5 | 35±5 | 45±5 | ||||

| Ra | 0.35±0.05um | 0.35±0.05um | 0.6-0.8um | ||||

| Tr | ≥85% | ≥85% | 77%±5 | ||||

| The following glass substrates are readily available in our stock for producing etched anti-glare (AG) glass. | |||||||||||||||||||

| Manufacturer | Mother Glass Dimensions(mm) | Thickness (mm) | |||||||||||||||||

| 0.4 | 0.5 | 0.55 | 0.7 | 0.75 | 0.8 | 1 | 1.1 | 1.3 | 1.5 | 1.8 | 2 | 2.5 | 2.9 | 3.0 | 3.2 | 5.0 | 6.0 | ||

| Corning | 1500*1900 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ||||||

| CAIHONG | 1520*955 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ||||||||||

| PANDA | 1300*1100 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |||||||

| Dragontrail | 1524*952.5 | ◎ | ◎ | ◎ | ◎ | ◎ | |||||||||||||

| CSG glass | 1300*1100 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |||||

| XING YI glass | 1830*1220 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |||||

| AGC Sadalime | 1092.2*1244.6 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | |||

Why Does Kariyo's Anti-Glare Etched Glass Offer a Sharper and Clearer Visual Experience?

Dual Technology: Fighting Glare and Random Sparkle Simultaneously

Our diagram shows how uniform etching diffuses light evenly, unlike conventional AG that causes sparkle and graininess.

Engineered Surface for Sharp Imagery and Reduced Eye Strain

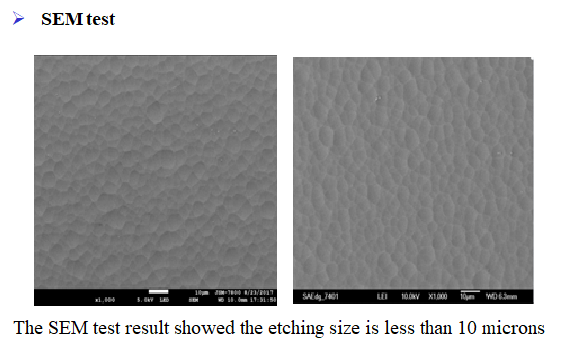

This SEM reveals our exceptionally even surface texture, which eliminates random sparkle and glare hotspots effectively.

Controlled Depth and Shape for Consistent Performance

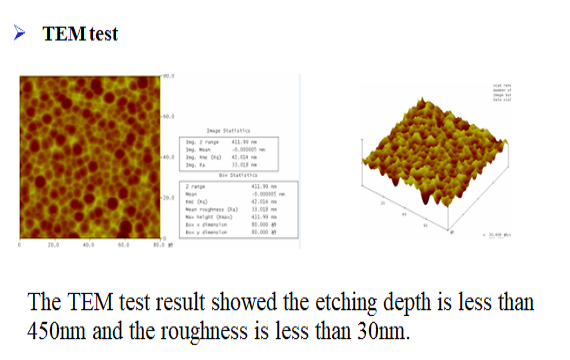

Our TEM analysis confirms the consistent etch profile that prevents light distortion and sparkle, ensuring true image quality.

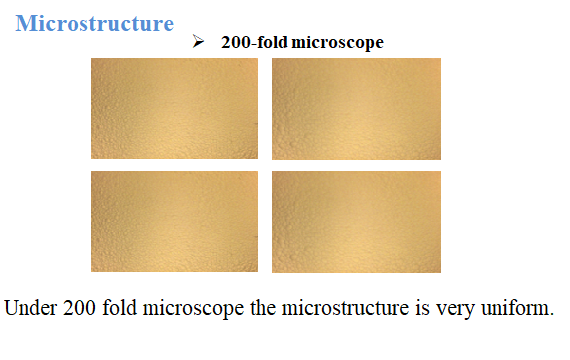

Consistent Nano-Etching for Minimal Graininess

Our uniform Anti Glare Etched Glass microstructure reduces sparkle and glare for a crystal-clear, comfortable view.

Premium Anti-Glare Glass from AGC Dragontrai, Corning and More | Always in Stock for Faster Lead Times

Anti-Glare Etched Glass: The Ultimate Display Solution for High-Performance Touch Screens

- Wide Application

- Standard Solutions for Automotive Displays

| Gloss | 125±10(60°) |

| Haze | 5±2 |

| Hz(E)C | 4.5±2.5 |

| DOI | ≥95% |

| SCE | ≤0.7(Y) |

| Ra | ≤ 0.05um |

| Rz | ≤0.5um |

| RSM | ≤35um |

| Sparkle | 254PPI,SIM≤1.2,DIM≤1.5 |

Precision-Crafted Anti-Glare Glass: Tailored Solutions from Cutting to Eco-Conscious Production (6)

Download Kariyo's Anti-Glare Etched Glass Certifications & Quality Control Documents.

Explore Our Anti-Glare Etched Glass Manufacturing Process | Video Series

- Precision Cutting for Anti-Glare Etched Glass with Minimal Material Waste

- High-Tolerance Screen Printing for Precise Anti-Glare Pattern Masking

- Uniform Surface Frosting for Consistent Anti-Glare Etched Glass Diffusion

- Controlled Chemical Etching to Engineer Optimal Anti-Glare Glass Haze

- Chemical Polishing for a Smooth, Durable Anti-Glare Glass Surface

Customized Services

We provide tailored solutions for various end products. The glossiness, haze, and roughness of the Anti-Glare Etched Glass can all be customized according to your requirements.

Application cases of Kariyo's Anti-Glare Etched Glass in new energy vehicles

Kariyo's inspection equipment for Anti-Glare Etched Glass (4)

Anti-Glare Etched Glass is glass treated with a chemical etching process to create a matte surface, reducing light reflection from 8% to under 1%7. This minimizes glare, enhances readability in high-light environments, and provides a clearer visual experience for displays and industrial equipment.

It is essential for industrial control panels, medical imaging displays, and new energy vehicle interfaces. Its anti-reflective properties ensure clear visibility in critical environments, reducing operational errors and enhancing performance in high-precision settings.

The chemical etching process creates a micro-roughened surface that is inherently resistant to scratches, abrasion, and chemicals. This ensures long-term reliability without additional coatings, making it ideal for demanding applications like outdoor equipment and medical devices.

Automated production processes minimize human error, ensuring uniform etching and consistent gloss levels. Rigorous testing for haze, reflectivity, and abrasion resistance guarantees batch-to-batch reliability for industrial clients.