Custom Touch Panel Cover Glass Manufacturer| Precision-Crafted for HMI Displays

- Custom Size: 3.5″ to 32″

- Material : Schott, Corning, AGC, PPG and Pilkington including Borofloat® Glass, Eagle XG™, Corning Gorilla™Glass, Starphire™, Schott D263™, Dragontrail™.etc.

- Shape: customized ( rectangle, square, irregular, round )

- Thickness: 0.15mm, 0.2mm, 0.33mm,0.55mm,0.7mm, 0.8mm,1.1mm, 1.8mm,2.0mm, 2.5mm,3.0mm, 4.0mm,5.0mm,6.0mm

- coating:Anti Fingerprint coating ,Anti Reflective coating ,Anti-Glare coating,antimicrobial coating

- Etching:Anti-Glare Etching,Text or graphic etching

China-manufactured touch panel cover glass for industrial/kiosk/medical/vehicle

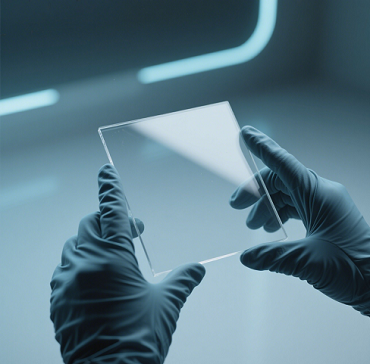

Custom touch panel cover glass Manufacturing Services | Precision & Durability

Industrial-Grade Touch Panel Cover Glass Solutions

Precision-Cut, Tempered & Customized for HMI/Kiosk/Medical/Vehicle Applications

Engineered for Demanding Environments

We manufacture mission-critical touch panel cover glass with CNC cutting, chemical tempering, and advanced coatings. Trusted by industrial OEMs for:

✔️ 9H hardness & 500°C thermal shock resistance

✔️ Anti-scratch/IP65 sealed surfaces

✔️ MIL-STD-810G vibration compliance

Core Capabilities

-

Laser/CNC Precision Cutting

-

±0.05mm tolerance for industrial HMI integration

-

Custom shapes/sizes with crack-free edges

-

-

Chemical Tempering (0.3-3mm)

-

5x stronger than standard glass (700+ MPa surface compression)

-

Lightweight solution for portable medical devices

-

-

CNC Edge Grinding

-

45° beveled/polished edges to prevent micro-cracks

-

Optimized for glove-compatible touchscreens

-

-

Performance Coatings

Coating Type Function Industrial Benefit Anti-glare Reduce reflections Sunlight-readable displays EMI Shielding Block interference Medical/Sensitive equipment Oleophobic Resist oil/grease Workshop contaminant protection -

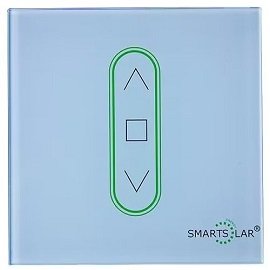

Functional Markings

-

Screen-printed button icons (150+ Pantone matches)

-

Chem-etched tactile guides for gloved operation

-

Industrial Applications

-

Factory Automation : Control panels resistant to coolant/oil

-

Medical Kiosks : Antimicrobial surfaces with IPA wipeability

-

Construction Vehicles : Vibration-proof dashboards (-40°C to 85°C)

-

Self-Service Terminals : 7M+ touch cycle durability

Why Global Manufacturers Choose Us

✅ Rapid Prototyping

3D files → Functional samples in 5 business days

✅ Bulk Production Advantage

-

500,000+ monthly capacity

-

30% cost reduction on 10K+ orders

✅ Compliance Guarantee

RoHS/REACH/IP65/MIL-STD certified

✅ Lifetime Support

Technical consultation for thermal/mechanical stress design

Mission-Critical Touch Panel Cover Glass Solutions for Medical, Automotive & Industrial HMI

Automotive & Transportation

Rugged cover glass enables curved, large-format cockpit displays (double/triple screens) with Etching anti-glare for sunlight readability and vibration resistance. Chemically strengthened glass (1.3mm thickness)

Industrial Control Systems

Features EMI shielding to block electrical noise in factory settings, IK8-IK10 impact resistance for harsh operations, and anti-fingerprint surfaces. IP65-sealed zero-bezel designs eliminate dust/moisture traps and streamline sanitation—critical for manufacturing panels and HMIs.

Medical Equipment

Antimicrobial-coated cover glass inhibits pathogen growth on surgical displays and diagnostic interfaces. Smooth, seamless edges (achieved via perimeter/optical bonding) support frequent chemical sterilization and hygienic compliance.

Marine & Outdoor

Saltwater-resistant coatings prevent corrosion in navigation systems. Advanced optical bonding with UV filters reduces glare and ensures readability in direct sunlight, while materials withstand humidity and thermal shocks

3.0mm Soda-Lime Glass Touch Panel Cover Glass ,Anti glare coating

High temperature ceramic ink

Heat tempered glass

4.0mm custom AGC soda lime glass

Chemically strengthened or Heat tempered glass

Non-glare Touch Panel Cover Glass,Anti-fingerprint coating

1.8mm Custom Corning®Gorilla® Glass

Chemically strengthened &Non-glare Touch Screen Glass

Antimicrobial corning gorilla glass

2.0mm custom Corning®Gorilla® Glass

Chemically strengthened &Etching anti-glare Touch Panel Cover Glass

EMI Shielding Touch Glass

3.0mm Custom Aluminosilicate glass

Chemically strengthened &Non-glare Touch Screen Glass

Anti-fingerprint coating

6.0mm custom China xinyi glass,7H Hardness Cover Glass Panel

Heat tempered or Chemically strengthened

Anti-Glare Touch Panel Cover Glass

1.3mm custom AGC Dragontrail™ glass

Chemically strengthened &Anti-reflective Touch Panel Cover Glass

Anti-Glare touch screen glass

4.0mm custom China CSG glass

Chemically strengthened or Heat tempered glass

7H Hardness Cover Glass Panel,Anti-fingerprint coating

3.0mm custom Aluminosilicate glass

Heat tempered&Etching anti-glare Touch Panel Cover Glass

Clear even under strong light

1.0mm custom Corning®Gorilla® Glass

Chemically strengthened &Anti-Glare Touch Panel Cover Glass

Multi-color silk screen

0.55mm custom Corning®Gorilla® Glass

Chemically strengthened &Anti-reflective Touch Panel Cover Glass

Anti-fingerprint coating

2mm custom Corning®Gorilla® Glass

Chemically strengthened &Etching anti-glare Touch Panel Cover Glass

Anti-fingerprint coating

1.1mm custom AGC Dragontrail™ glass

Chemically strengthened &Anti-reflective Touch Panel Cover Glass

Anti-fingerprint coating

3.0mm Aluminosilicate glass

Chemically strengthened,Etching anti-glare Glass

Anti-reflective Touch Panel Cover Glass

5.0mm custom soda lime glass(China CSG glass)

Chemically strengthened &Etching anti-glare Touch Panel Cover Glass

Anti-reflective glass.

1.0mm Custom Corning®Gorilla® Glass

Chemically strengthened &Non-glare Touch Screen Glass

Antimicrobial corning gorilla glass

Custom Safety Tempered Glass

Application of tempered safety glass in industries other than touch screens

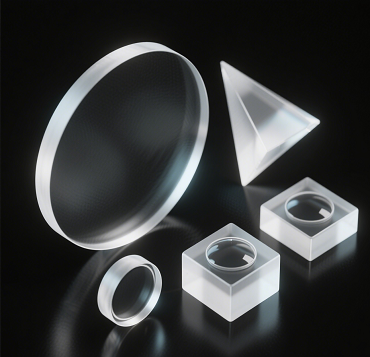

Precision Industrial Optical Lenses

For industrial OEMs seeking high-performance imaging solutions, our precision industrial optical lenses optimize critical applications—from IR optical lenses for machine vision systems to custom aspheric lenses manufacturing. Engineered with UV fused silica lenses (industrial grade) and high-temperature resistant optical lenses, we deliver robust components for semiconductor inspection, thermal imaging, and harsh-environment automation.

Industrial Schott® Glass Touch Panel Cover Glass

Engineered with Schott glass for extreme thermal resistance (-50°C to 450°C), our touch panel cover glass withstands foundry/autoclave environments. Chemically strengthened to 800 MPa, it resists thermal shock and acid corrosion. CNC precision-cut for seamless HMI integration.

Industrial Dragontrail™ Touch Panel Cover Glass

Engineered with AGC Dragontrail glass for 2.5x higher impact resistance than soda-lime glass, our touch panel cover glass survives drops in logistics scanners and rugged HMIs. Chemically tempered to 9H hardness, it withstands abrasion from tools and debris in construction machinery.

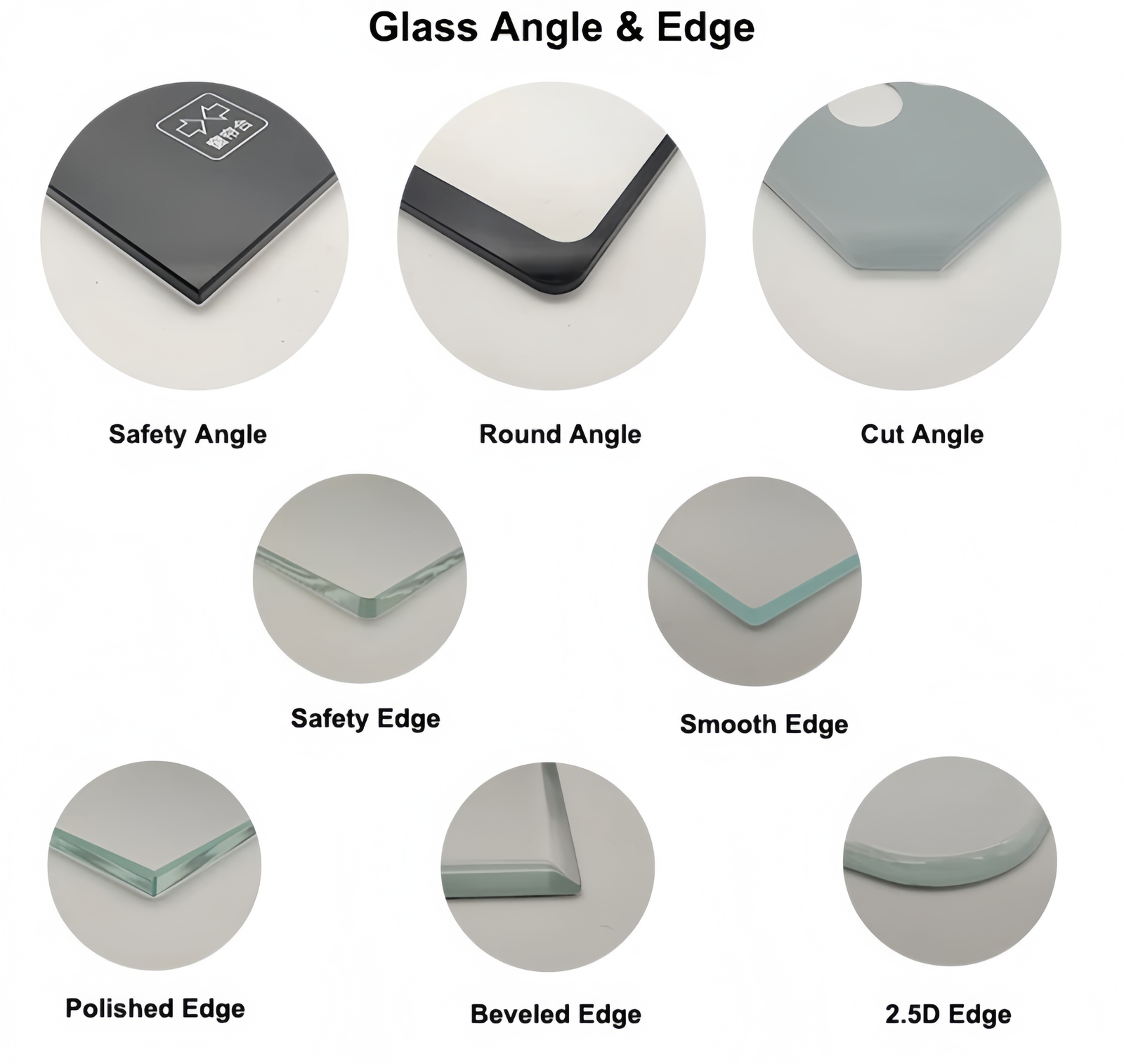

Touch Panel Cover Glass – Custom CNC edge

1. Safety Angle Edge

Touch Panel Cover Glass with a Safety Angle Edge reduces sharpness for safer handling. This edge type minimizes accidental cuts while maintaining a sleek appearance for modern devices.

2. Polished Edge

Touch Panel Cover Glass with a Polished Edge achieves a glossy, reflective finish for high-end devices. This process enhances scratch resistance and elevates the product’s visual appeal.

3. Beveled Edge

The Beveled Edge on Touch Panel Cover Glass adds a stylish angled cut for better grip and aesthetics. This edge type is widely used in smartphones and tablets for a premium look.

4. 2.5D Edge

Touch Panel Cover Glass with a 2.5D Edge features a gently curved surface for smooth swiping. This design improves touch responsiveness and ergonomics in modern touchscreens.

Custom tempered glass

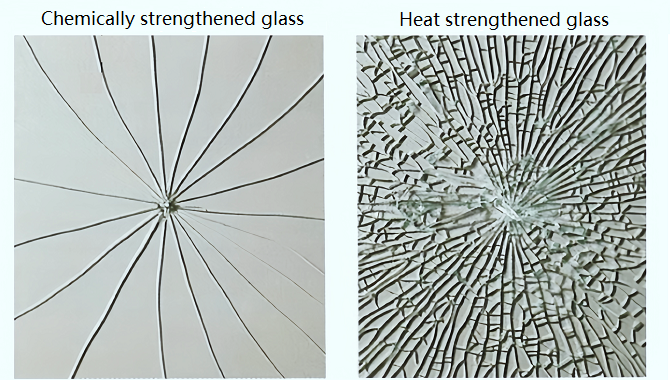

Chemically strengthened glass vs. Heat strengthened glass (Touch Panel Cover Glass Processing)

Chemical Strengthening: Uses ion exchange (e.g., K⁺ replacing Na⁺) to create a compressive stress layer, improving impact and scratch resistance. Ideal for thin glass (0.1-3mm) like smartphone covers but has higher costs.

Physical Tempering : Rapid cooling (air quenching) forms surface stress for high strength at lower cost, but requires thicker glass (≥3mm) and has weaker edges. Common in larger touchscreens (e.g., ATMs, industrial panels).

Custom Ceramic Ink Printing for Touch Panel Cover Glass

Industrial manufacturers seeking durable solutions for 10.1 inch touch panel cover glass benefit from our precision Ceramic Ink Printing process, which applies heat-resistant, screen-printed ceramic inks to create scratch-resistant conductive layers (e.g., edge electrodes) and decorative elements. This high-temperature firing technology delivers exceptional adhesion and environmental stability specifically for 10.1 inch touch panel cover glass, ensuring long-term performance in demanding industrial environments including control panels, HMI devices, and ruggedized equipment. The result is enhanced functionality and aesthetics tailored for reliable 10.1 inch touch panel cover glass applications.

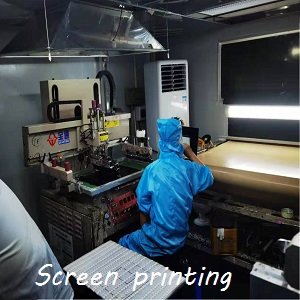

Precision Multi-Color Screen Printing for Touch Panel Cover Glass | ±0.1mm Registration

Our advanced multi-color screen printing technology delivers exceptional registration accuracy for touch panel cover glass, enabling high-resolution, edge-to-edge designs with perfect color alignment. This precision silk-screen process supports:

✓ Complex patterns, intricate logos & delicate functional markings

✓ Vibrant ceramic ink reproduction with ±0.1mm tolerance

✓ Cost-effective small-batch customization to your specifications

Industrial-Grade Functional Glass Coatings Guide: AG, AR, AF & Antimicrobial Glass Solutions

Non-Glare Coating(Anti-Glare Treatment) for Industrial Touch Panel Cover Glass

Technology: Engineered for touch panel cover glass, our anti-glare treatment creates a controlled micro-rough surface (Ra 0.03-0.5μm) via etching or ceramic particle coating.

Performance: Reduces reflectivity to <4% on touch panel cover glass surfaces, diffusing ambient light uniformly even in 500-1000 lux environments.

Advantages: Ensures sunlight readability without image sharpness loss – critical for outdoor-rated touch panel cover glass in harsh settings.

Applications: Ideal for industrial-grade displays: rugged outdoor kiosks, automotive HMI touch panels, and control panels requiring glare-resistant cover glass solutions.

Industrial Anti-Reflective Coating for Touch Panel Cover Glass

Technology: Multi-layer dielectric coating (4-8 layers, λ/4 optical thickness) engineered specifically for durable touch panel cover glass, enhancing optical clarity in harsh environments.

Performance: Achieves <0.5% reflectivity (380-780nm) on touch panel cover glass surfaces, maximizing light transmission to >95% even under industrial lighting.

Advantages: Critical for color-critical industrial touch panel cover glass – boosts contrast by 300% while resisting scratches and chemical exposure.

Applications: Mission-critical displays: medical diagnostic touch panels, rugged retail POS systems, and scratch-resistant cover glass for industrial tablets operating in high-contamination areas.

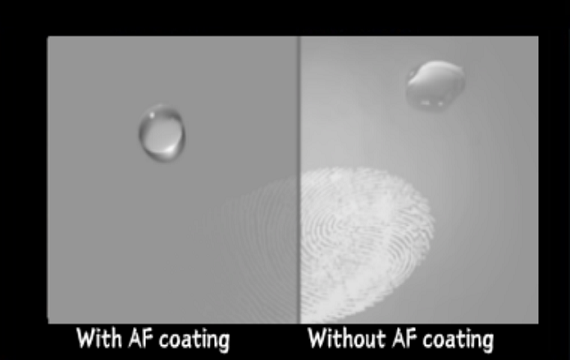

Durable Anti-Fingerprint Coating for Industrial Touch Panel Cover Glass

Technology: Fluorosilane-based nanocoatings (10-100nm) chemically bonded to touch panel cover glass surfaces, creating permanent oleophobic protection even after 10,000+ cleaning cycles.

Performance: Maintains >110° water / >80° oil contact angles on industrial-grade touch panel cover glass, reducing fingerprint visibility by 80% in high-contamination environments.

Advantages: Critical for hygienic touch panel cover glass – enables 5-second wipe cleaning while preserving optical clarity and chemical resistance to industrial disinfectants.

Applications: FDA-compliant food processing interfaces, medical diagnostic touch panels, heavy-use public kiosks, and grease-resistant cover glass for industrial HMI displays.

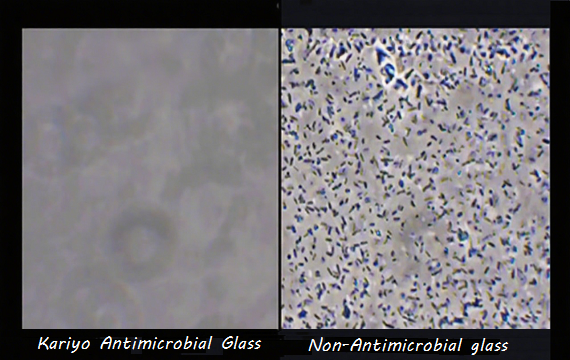

Antimicrobial Touch Panel Cover Glass with Silver Ion Technology

Technology: We integrate silver ions (Ag⁺) into industrial-grade touch panel cover glass via:

✓ Bulk infusion during high-pressure production

✓ Permanent surface coating (sputtering/sol-gel) compatible with tempered/chemically strengthened cover glass

Performance: Kills 99.9% microbes on touch panel surfaces while maintaining >98% optical clarity after 50,000+ cleaning cycles (ISO 22196 certified).

Applications: Critical hygiene environments: medical diagnostic touch panels, ATM cover glass, and public touch panel cover glass for high-traffic kiosks requiring microbial resistance.

Key Quality Control Parameters for Touch Screen Glass Processing

Precision CNC Machining for Industrial Touch Panel Cover Glass

Critical for achieving optical-grade edges on tempered touch panel cover glass, our CNC process delivers:

✓ Dimensional accuracy: Holds ±0.05mm tolerance for seamless integration into rugged HMI enclosures

✓ Surface finish: Achieves Ra ≤ 0.4μm roughness on cover glass perimeters, eliminating secondary polishing

✓ Edge integrity: Guarantees zero micro-cracks at 100x magnification – vital for chemically strengthened touch panel cover glass in medical/automotive applications

Industrial Toughening Solutions for High-Performance Touch Panel Cover Glass

Chemical Tempering: Generates 400-800MPa surface compressive stress (DOL ≥40μm) on touch panel cover glass, preventing scratch propagation in abrasive industrial environments.

Physical Tempering: Achieves ≥150MPa 4-point bend strength for impact-resistant touch panel cover glass used in automotive/military HMIs.

Fragmentation Control: Maintains 40-60 particles/cm² (EN 12150 certified) ensuring safety-critical cover glass fragmentation in medical devices.

Post-Tempering Flatness: Holds ≤0.1mm warp for seamless integration into multi-touch panel assemblies requiring optical precision.

Industrial-Grade Screen Printing Solutions for Touch Panel Cover Glass

Print Registration: Achieves ±0.1mm alignment accuracy on multi-layer touch panel cover glass, enabling complex logos/sensors integration for medical/automotive HMIs.

Ink Adhesion: Guarantees 5B rating (ASTM D3359) even after 500+ thermal cycles – critical for outdoor touch panel cover glass in extreme environments.

Curing Process: Complete polymerization at 150°C ensures chemical-resistant functional layers compatible with chemically strengthened cover glass substrates.

Process and Specifications

- Main production process

- Material thickness specifications

- China's Touch Screen Glass for Global Industrial Applications

The following are the specific thickness specifications of several glass materials commonly used by Kariyo (based on the official public data of each brand, some models may have more detailed specifications)

1. Corning®Gorilla® Glass

Thickness Range: 0.4mm – 2.0mm

Standard Thickness Options (common models):

-

Corning®Gorilla® Glass 3/4/5/6/Victus:

0.4, 0.5, 0.55, 0.6, 0.7, 0.8, 1.0, 1.1, 1.2, 1.5, 1.8, 2.0 -

Typical Applications:

-

Smartphones:

0.5–0.7mm -

Tablets/Laptops:

0.8–1.2mm

-

2. Schott D263™ (Ultra-thin Borosilicate Glass)

Thickness Range: 0.03mm – 1.1mm

Standard Thickness Options:

-

Standard Models:

0.03, 0.05, 0.07, 0.1, 0.15, 0.21, 0.3, 0.4, 0.5, 0.55, 0.7, 1.0, 1.1 -

Special Applications:

-

Ultra-Thin Glass (UTG):

0.03–0.1mm -

Sensor Cover Glass:

0.3–0.7mm

-

3. AGC Float Glass

Thickness Range: 0.1mm – 25mm

Standard Thickness Options:

-

Ultra-thin/Thin Glass:

0.1, 0.2, 0.3, 0.4, 0.5, 0.7, 1.0, 1.1, 1.3, 1.5, 1.8, 2.0 -

Architectural/Industrial:

2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 15.0, 19.0, 25.0

4. Borofloat® Glass (Schott)

Thickness Range: 0.7mm – 25mm

Standard Thickness Options:

-

Standard Models:

0.7, 1.0, 1.3, 1.8, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 15.0, 20.0, 25.0 -

Labware Applications:

3.0–6.0mm

5. AGC Dragontrail™

Thickness Range: 0.3mm – 2.0mm

Standard Thickness Options:

-

Dragontrail X/Pro:

0.3, 0.4, 0.5, 0.55, 0.6, 0.7, 0.8, 1.0, 1.2, 1.5, 1.8, 2.0 -

Smartwatch Cover Glass:

0.3–0.5mm -

Automotive Displays:

1.0–1.8mm

6. CSG Glass (China Southern Glass)

Thickness Range: 0.33mm – 25mm

Standard Thickness Options:

-

Float Glass:

0.33, 0.4, 0.5, 0.7, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 15.0, 19.0, 22.0, 25.0 -

Solar Glass:

2.0–4.0mm

7. Xinyi Glass

Thickness Range: 1.1mm – 25mm

Standard Thickness Options:

-

Architectural Glass:

1.1, 1.6, 1.8, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0, 10.0, 12.0, 15.0, 19.0, 25.0 -

Low-E Coated Glass:

3.0–12.0mm

China’s Touch Screen Glass: Manufacturing Excellence for Global Industrial Applications

Touch screen glass has evolved from a basic protective layer into a sophisticated engineered component that defines user experience across industrial and consumer applications. As the global touch panel market surges toward new efficiency and durability benchmarks, China has emerged as a powerhouse—not just in volume production but in high-precision innovation. This transformation positions Chinese manufacturers at the forefront of supplying mission-critical touch solutions for industrial equipment, automotive interfaces, and public interactive systems worldwide.

1. China’s Touch Screen Glass Evolution: From Follower to Innovator

The journey reflects three distinct technological waves:

-

Sodium-Calcium Silicate Glass Era (pre-2013): Early domestic production relied on float glass processes. While scratch-resistant, these panels suffered from poor drop resistance (fragility limits at ~0.8m), restricting use to basic devices14.

-

High-Aluminosilicate Breakthrough (2013-present): Inspired by Gorilla Glass, companies like CNMC (Kelee) and Dongxu Group pioneered ion-exchangeable compositions. Using overflow downdraw and float methods, they achieved surface compressive strength exceeding 700 MPa—rivaling imported alternatives14. Today, this category dominates mid-range automotive displays and industrial HMIs.

-

Lithium-Aluminosilicate Dominance (2018+): Leaders like Rainbow Group and Sichuan Xuhong now mass-produce this premium grade via overflow fusion. With fracture toughness up to 0.85 MPa·m¹/² and compatibility with ultrathin designs (0.4–1.2mm), it’s essential for foldable displays and aerospace instrumentation1014.

Table: China’s Touch Screen Glass Technology Evolution

| Timeframe | Technology | Key Players | Strength Limit | Primary Applications |

|---|---|---|---|---|

| Pre-2013 | Sodium-Calcium Glass | China Building Materials | Low (<1m drop) | Basic handsets, low-cost devices |

| 2013-2018 | High-Aluminosilicate | Kelee, Dongxu Group | ~700 MPa | Automotive, industrial HMIs |

| 2018-Present | Lithium-Aluminosilicate | Rainbow Group, Xuhong Opto-Electronic | 15-20x stronger | Foldables, aerospace, military |

2. Precision Manufacturing: Decoding Core Production Processes

Laser Cutting & CNC Edge Profiling

Ultrafast femtosecond lasers cut complex contours (0.1mm tolerance) without microcracks—critical for curved automotive displays13. Post-cutting, CNC machines apply precisely angled bevels (22.5°–45°) using diamond-embedded wheels. This eliminates edge stress points, boosting structural reliability by 30%13.

Strength Enhancement Technologies

-

Chemical Strengthening: Submersion in molten KNO₃ at 410°C triggers Na⁺/K⁺ ion exchange. Optimized durations (4–16 hours) create 40–100μm compression layers, yielding 15–20x strength gains113.

-

Thermal Tempering: For panels >3mm thick (e.g., kiosks), rapid air-cooling locks in 120–200 MPa surface compression. When shattered, fragments granulate rather than splinter—meeting ANSI Z97.1 safety standards13.

Advanced Surface Functionalization

Demand grows for multi-layer optical coatings tailored to harsh environments:

-

AG (Anti-Glare): Acid etching creates 0.1–0.3μm surface roughness, cutting reflectivity to <2%—ideal for sunlight-readable outdoor kiosks1315.

-

AR/AF (Anti-Reflective/Anti-Fingerprint): Magnetron-sputtered SiO₂/TiO₂ stacks achieve >92% transmittance. Paired with fluorinated coatings, they maintain >110° water contact angles for easy cleaning5.

-

DLC (Diamond-Like Carbon): CVD-deposited carbon matrices (1,500–2,500 HV hardness) shield against sand erosion in mining or military systems13.

Table: Touch Screen Glass Surface Treatments Compared

| Process | Technical Principle | Key Metrics | Industrial Use Cases |

|---|---|---|---|

| AG Treatment | Hydrofluoric Acid Etching | Reflectivity <2%, Haze 10-40% | Outdoor Kiosks, Medical Devices |

| AR Coating | Multi-Layer Oxide Sputtering | Transmittance >92% | Automotive Displays, Avionics |

| AF Coating | Fluoropolymer Deposition | Contact Angle >110° | Food Service, Public Terminals |

| DLC Coating | Plasma-Enhanced CVD | Hardness 1500-2500 HV | Heavy Equipment, Defense |

3. Market Landscape: Where China Excels

China’s touch glass sector hit ¥80.36 billion ($11B USD) in 2023, with projections nearing ¥100 billion by 2025214. Beyond smartphones, key growth drivers include:

-

Automotive Displays: 15–20% annual demand surge for curved, strengthened glass compatible with LIDAR/AR HUDs1014.

-

Industrial HMIs: Custom drill holes (for buttons, card readers) and EMI shielding for factory automation13.

-

Outdoor Kiosks: Explosion-resistant laminated units (up to 35mm thick) with solar-load resistance (85°C+ operation)15.

Leading manufacturers like Lens Technology and Biel Crystal dominate global supply chains, supplying 60%+ of Apple/Samsung panels. Their integrated facilities handle everything from laser cutting to lamination—slashing lead times by 40% versus competitors214.

4. Industrial-Grade Applications: Beyond Consumer Electronics

Extreme Environment Solutions

-

GreenTouch’s Outdoor Kiosks: Integrate 8mm AG-coated glass with heating elements to prevent fogging/icing (-30°C to 70°C operational range). IP66-rated sealing combats dust/moisture in ports or construction sites15.

-

Zytronic’s Blast-Resistant Units: Polycarbonate-glass laminates withstand 15kJ impacts—certified for ATMs and petrol station pay points13.

Customization Capabilities

Chinese producers specialize in niche geometries:

-

Perimeter Grooving: 0.3mm-deep channels for gasketing medical displays (ISO 13485 compliant)13.

-

Accessibility Features: Tactile laser-etched braille for vision-impaired users in transit hubs13.

Table: China’s Major Touch Glass Makers: Capabilities vs. Markets

5. Global Competitiveness: Strategic Shifts

While Corning and AGC lead in patent-rich compositions (e.g., Gorilla Glass Victus 2), Chinese firms counter with:

-

Faster Prototyping: 10–15 day sample turnaround for custom coatings/thicknesses7.

-

Cost-Effective Scaling: Automated CNC lines output 500k+ panels monthly at 30% lower cost than US/EU peers14.

-

Localized Supply Webs: 90%+ of materials (high-purity quartz, polishing compounds) now sourced domestically—avoiding import bottlenecks2.

6. Tomorrow’s Touch Glass: Emerging Frontiers

-

Embedded Sensors: Direct printing of indium tin oxide (ITO) grids enables touch functionality without separate layers—slimming displays by 0.3mm5.

-

Self-Healing Coatings: Microcapsule-based polymers repair minor scratches when heated (40°C+), extending service life in rugged tools14.

-

UTG Flex: 30μm chemically strengthened glass enables 200k+ folding cycles for wearables and rollable TVs10.

For industrial buyers, China’s touch screen glass sector delivers more than cost efficiency. With vertically integrated R&D, aggressive process innovation, and expanding certifications (ISO/TS 16949, MIL-STD-810), it’s now a strategic source for performance-critical applications—from desert-deployed machinery to subzero logistics terminals. Partnering with tier-1 Chinese suppliers means accessing tomorrow’s touch technologies, engineered today.

AG Glass (Anti-Glare Glass) is touch panel cover glass treated with a micro-etching process. This creates a slightly matte surface that diffuses reflections from ambient light sources. Key benefits for industrial applications include:

Reduced Glare & Reflections: Significantly minimizes distracting reflections in bright environments (factories, outdoors).

Improved Sunlight Readability: Enhances screen visibility under direct light, crucial for HMI panels and outdoor kiosks.

Enhanced Optical Clarity: Maintains image sharpness while scattering reflected light.

Durability: Provides the same robust, scratch-resistant surface expected from quality cover glass.

Ideal for industrial displays, medical devices, control panels, and any touch interface requiring clear viewing in challenging lighting.

AR Glass (Anti-Reflective Glass) is touch panel cover glass with specialized coatings that minimize surface reflections across all light angles. Key advantages for industrial applications include:

-

Ultra-Low Reflectivity: Reduces >98% of surface glare for crisper displays in high-light environments (factories, laboratories).

-

Enhanced Optical Clarity: Maintains true color accuracy and image sharpness—critical for medical devices and precision HMIs.

-

Improved Touch Readability: Virtually eliminates distracting reflections on control panels, ATMs, and diagnostic equipment.

-

Durability: Combines hard-coated scratch resistance with chemical resilience for harsh industrial settings.

Ideal for high-precision interfaces: medical imaging displays, aviation controls, instrumentation, and touch panels demanding distortion-free visibility.

AG Glass vs. AR Glass: Key Differences

-

Surface Treatment:

-

AG Glass (Anti-Glare): Features a micro-etched matte surface that diffuses ambient light, reducing glare in bright settings (e.g., factories, outdoor kiosks).

-

AR Glass (Anti-Reflective): Uses multi-layer optical coatings to cancel out reflections, achieving >98% reflection reduction for precision displays.

-

-

Optical Performance:

-

AG: Prioritizes glare reduction with slight haze (1-10%), ideal for sunlight readability.

-

AR: Maximizes clarity & color accuracy (<0.5% reflectivity), critical for medical/aviation HMIs.

-

-

Industrial Applications:

-

AG Glass: Best for high-glare environments (warehouse HMIs, outdoor terminals, industrial controls).

-

AR Glass: Optimal for high-precision displays (surgical monitors, lab equipment, aviation dashboards).

-

-

Durability:

-

Both offer robust scratch resistance, but AR’s coated surface may require gentler cleaning vs. AG’s etched surface.

-

Choose AG for glare-prone settings; AR for reflection-sensitive precision interfaces.

Custom Touch Screen Glass product display

Frequently asked questions about Kariyo

Action is the only way to verify the truth,Kariyo has always focused on glass processing.

A: Kariyo’s ion-exchange strengthened glass achieves Mohs 8+ hardness (vs. industry average 6-7), resisting keys, tools, and abrasives. Our proprietary nano-ceramic layer passes 15,000+ steel wool cycles in ASTM tests. Third-party verified 5x longer lifespan in rugged environments like warehouses and outdoor kiosks.

A: Advanced anti-static coating enables <0.1N touch force detection even through 3mm-thick work gloves. Hydrophobic surface tech maintains 95% touch accuracy in rain/humidity (IP68-rated). Supports 10-point multi-touch with zero lag (-30°C to 85°C) – critical for medical, industrial, and automotive displays.

A: Yes. Our nano-etching & AR coating cuts reflection by 75% (vs. standard glass) while achieving >95% light transmission. Permanent oleophobic layer reduces fingerprint smudges by 90% and simplifies cleaning. Ideal for outdoor POS systems, marine displays, and surgical equipment.

A: Kariyo delivers 0.15mm to 6mm thickness (including ultra-thin 0.15/0.3/0.4/0.5/0.7mm for wearables). Custom cuts up to 2,500mm x 1,800mm with ±0.05mm tolerance. Options include curved, hole-punched, or anti-microbial glass – all with 48-hour prototyping.

A: Absolutely. Our 580°C strain point (industry standard: 520°C) withstands solder reflow and lamination. CTE-matched to sensor films prevents delamination. RoHS/REACH-certified with no optical distortion after thermal cycling – trusted by aerospace and automotive Tier 1 suppliers.